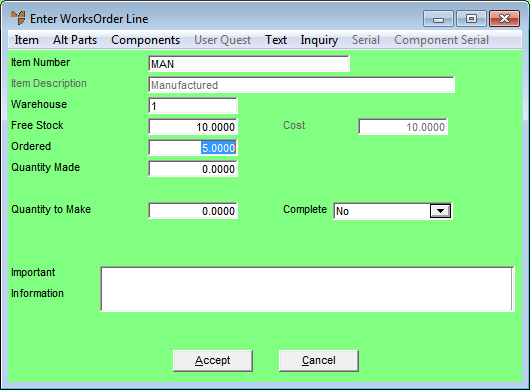

You add kit items to a works order using the Enter WorksOrder Line screen. You also use this screen to maintain the component items associated with a kit item.

Refer to "Creating a New Works Order" or "Recalling a Works Order".

If you selected to add, insert or edit an item, Micronet displays the Enter WorksOrder Line screen.

|

|

Field |

Value |

|

|

Item Number |

Enter the number of the kit item you want to add to the works order. The item must belong to a manufactured category. Micronet will pre-load all the component items for the kit item. You can also press Tab or Enter to select an item. |

|

|

Item Description |

Micronet displays the description of the selected item. |

|

|

Warehouse |

Micronet displays your default warehouse. |

|

|

Free Stock |

Micronet displays the quantity of the kit item available. |

|

|

Ordered |

Enter the quantity of this kit item that you want to make. |

|

|

|

Reference If your company is configured for multiple bin locations and your userID allows you to edit bin locations, Micronet displays the Bin Locations and Quantities screen – refer to "Enter WorksOrder Line - Selecting Bins and Quantities" for more information. If Micronet has been setup to use the Main Bin Only or Priority Order and you do not have authority to edit bin locations, the selection of bins will be automatic and performed in the background. |

|

|

Quantity Made |

Micronet displays the quantity of the item on this works order that has already been manufactured and completed. This means that the works order has been recalled, the completed quantity entered and the completed items posted to stock. For more information about completing items on a works order, refer to "Works Order Creation - Edit - Complete All" or "Works Order Creation - Edit - Ask All". |

|

|

Quantity to Make |

For new works orders, leave this field blank. If you have recalled a works order because a quantity of the item has been manufactured and completed, enter the quantity of the item to be posted to stock. This can be less than the Ordered quantity. When the completed items are posted to stock (refer to "Works Order Creation - File - Post Completed Stock"), Micronet updates the Quantity Made on this screen with the quantity you enter in this field. As long as you don't select to complete the line (see the Complete field below), the item remains on the works order for later manufacture and completion. |

|

|

Complete |

For new works orders, leave this field set to No. You should also leave it set to No when you are posting a partial quantity of the item to stock, and you still want to post the remainder at a later time. You should only change this field to Complete This Line when you don’t want to manufacture any more of this item. When this field is set to Complete This Line and you post the completed items to stock, the item line can no longer be edited. |

|

|

Important Information |

Micronet displays any added text in the Item master file that is assigned to display as important information on works orders. |

If you selected to add an item, Micronet redisplays the Enter WorksOrder Line screen so you can add further kit items.

Micronet redisplays the Works Order Creation screen showing all the kit items added.